FD.BJC.com recently featured an exclusive report: Windey has successfully grid-connected the world's first 1,800V wind turbine, marking a breakthrough for Chinese wind power enterprises in high-voltage technology.

Amidst the vast Gobi Desert, where howling winds carry swirling sands, a wind turbine stands remarkably prominent. Recently, the world’s first 1,800V high-voltage wind turbine has steadily operated in such extreme conditions, converting wind energy into continuous green electricity. The grid connection of this 1,800V unit not only signifies a historic breakthrough for Chinese wind power enterprises in high-voltage technology but also demonstrates their successful mastery of "definition rights.” Windey is now leading the establishment of a new "high-voltage, high-efficiency" order in the wind power industry.

Challenges and Breakthroughs in Electrical System Upgrades for the Mega-Watt Era

The global wind power industry is rapidly advancing toward large-scale development, with onshore units targeting 10MW+ and offshore models accelerating toward 15MW+. According to CWEA data, China’s newly installed wind turbines in 2024 averaged 6,046kW per unit, an 8.1% year-on-year increase. Notably, offshore wind turbines of 10MW+ surged from 12.1% in 2022 to 58% in 2024, dominating the market.

However, while larger turbines enhance power generation capacity, they also exacerbate challenges: surging currents lead to increased cable losses, rising maintenance costs, and unprecedented performance-economic trade-offs for electrical systems. In this context, voltage elevation has become both a critical solution and an inevitable industry trend.

Globally, wind power enterprises have relentlessly pursued high-voltage technological upgrades. A R&D boom emerged around 2020, yet engineering implementation remained elusive for years.

Leveraging its deep expertise in 1,140V and medium-voltage doubly-fed technologies, along with full-industry-chain autonomy, Windey has triumphed in this competition. It achieved the world’s first and only large-scale application of 1,800V high-voltage technology, charting a new course for the industry.

Through stepwise breakthroughs from 1,140V to medium-voltage doubly-fed systems, Windey has built an end-to-end industrial chain encompassing R&D, core components, and system integration. By achieving 100% localization in previously bottlenecked areas like 2,300V-IGBT and high-voltage insulation materials, Windey halved the 1,800V technology R&D-to-industrialization timeline compared to peers. As industry experts note: "1,800V technology represents not just a technical milestone but a strategic pivot for reshaping wind power economics."

1,800V Technology: Multi-Dimensional Innovation Reshaping Industry Value

Voltage Elevation Drives Engineering Efficiency Leap

Traditional electrical systems grapple with excessive cabling complexity. More cables exponentially increase installation difficulty, with cable work consuming over 10% of project timelines, hindering grid connection speed and reliability.

Windey’s 1,800V technology, with its significant voltage elevation, has brought revolutionary changes. The cable cross-sectional area is reduced by 30%, directly leading to a substantial decrease in electrical installation complexity and correspondingly shortened labor hours. Taking a 10MW onshore wind turbine as an example, the application of this technology reduces the Levelized Cost of Energy (LCOE) by 3-5% over its lifecycle and improves electrical installation efficiency by 20%.

This breakthrough advances wind power toward greater economic viability and project scalability.

Reduced Line Losses Boost Green Energy Output

In practical applications, the advantages of Windey’s 1,800V technology are equally remarkable. Taking the field data from the 10.X-1800V model at Zhangbei Wind Farm as an example, this turbine achieves higher conversion efficiency with lower losses, resulting in an approximately 1% increase in annual power generation.

This 1% improvement means the wind farm can deliver significantly more clean electricity annually, providing greater support for alleviating energy pressures and advancing green development. It also accelerates the wind power industry’s progress toward the goal of "high output, low energy consumption."

Reliability Innovations for Ultra-Large Turbines

Ultra-large turbines have long faced industry-wide challenges during operation, including persistent issues such as cable twist overload and rotor overheating. Windey’s next-generation 1,800V solution has successfully resolved these problems through multi-dimensional technological innovations.

From leveraging multi-physics simulation for thermal optimization to redesigning motor rotor structures; from conducting 10,000-cycle fatigue tests under high currents to upgrading converter core modules—each technological breakthrough provides robust safeguards for the stable operation of ultra-large turbines. Field tests demonstrate that even under extreme operating conditions, the 10MW unit maintains "zero downtime," fully validating its reliability.

Full Industrial Chain Autonomy Forges Standard ‘Definer’

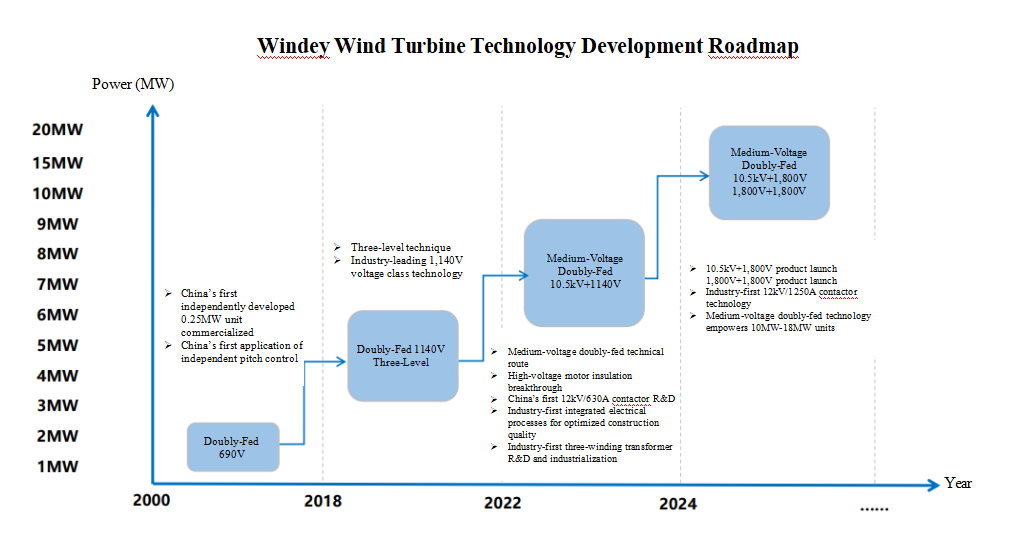

From early 690V doubly-fed units, through the 1,140V technological breakthrough, to the recent successful 1,800V rotor system upgrade, Windey has persistently advanced along the R&D path of "high-voltage & high-efficiency" wind power technology. This journey marks its transformation from an "industry pioneer" to a standard "definer," continuously expanding market boundaries with increasingly mature, controllable, and cost-effective technologies.

Since 2018, Windey has demonstrated foresight by pioneering the global proposal of 1,140V voltage class for wind turbines and developing a series of specialized electrical equipment. These devices, renowned for their superior performance and reliability, have not only become mainstream in domestic markets but also earned acclaim in international markets across Southeast Asia, Central Asia, and the Middle East. From 1,140V to 1,800V, Windey has completed a critical "triple jump," achieving full industrial chain integration for 1,800V technology.

In R&D design, production and manufacturing, core component supply, and system integration, Windey has established a complete and efficient industrial chain support system, providing robust backing for the industrial application of 1,800V technology products. In recent years, Windey has actively participated in industry standard formulation, leading the development of multiple industry standards in wind turbine electrical technology. It has unreservedly shared its technological achievements and practical experience in high-voltage wind power electrical systems with the industry. Simultaneously, Windey has introduced its 1,800V electrical system to the "Two Seas" (offshore and overseas) markets, achieving the leap from "Made in China" to "Created in China," contributing unique Chinese wisdom and solutions to global carbon neutrality goals.

The successful 1,800V deployment epitomizes China’s wind power evolution: from localization to global leadership, from technological catch-up to standard-setting. As Windey’s vision states: "We aim not to follow rules, but to define them." Under Windey’s leadership, China’s wind power industry is poised to thrive in the new "high-voltage, high-efficiency" era.

—— Edited by Zhou Xiaoyan, Polaris Wind Power Network